BRR TRUCKS – WHAT TO KNOW ABOUT YOUR PRO FINGERBOARD GEAR.

We brought in the latest pro gear from Blackriver Germany. The new trucks are amazing and the response has been overwhelming.

However we were surprised how many fingerboarders were over challenged by the trucks technical structure and new features.

Most fingerboarders never had a professional truck before and were not used to see fingerboard stuff as professional sports equipment. But that is just what we have with the trucks: The trucks took a giant leap away from simple toys. The reason for this is the fact fingerboarding is performed on a lot of different levels. For some people fingerboards are collectibles, simple toys or sports equipment. The first two groups already had a large range of goods to chose from while fingerboarders riding on a professional level were asking for an innovation on the truck sector.

The following article is not meant to praise the features of the truck. Instead the intention with the article is to explain, why the truck is built the way it is and how to fine tune the trucks correctly without ruining it by inproper use. Most single parts of the trucks are exchangeable similar to skateboard trucks. With most parts being replaceable there is a risk of kids full of curiosity needlessly taking apart the trucks just to assemble the trucks incorrectly causing single parts to be broken. To prevent fingerboarders from ruining their trucks we placed a instruction note inside the boxing with basic information on proper use of the product.

Nevertheless people do not seem to read instructions and we were facing numerous e-mails, phone-calls and letters from people asking questions about features explained in the instruction note. To ban the risk of ruining the trucks due to inproper use and to give the users all information necessary to understand the features of the trucks we decided to write this in depth guide placing it in the description of the article in the web shop.

Blackriver developed these trucks for pro use and just like with all professional sports equipment the product demands more attention and fine tuning than simple toys. A high tech product this small logically requires a lot more touch than products of lower quality so we advise every fingerboarder riding the BRR Trucks to read the following article carefully.

The top professional fingerboarders of the world swear by the trucks, since they provide all features necessary to guarantee fingerboarding at the highest level. How could they be wrong? The way to achieve the same insight in the usage of the trucks professional riders have is to understand the features of the trucks. We want you to ride the trucks having fun because they are of the highest standard available. We do not want you to break them due to inproper use.

HERE WE GO, WHAT DO I GET?

Each of the two trucks consists of:

• 1 Baseplate

• 1 Hangar with inserted passing axle pin

• 1 Pivot cup in the baseplate

• 2 Nuts for the axle pins

• 1 Kingpin in the baseplate

• 1 Kingpin nut

• 1 Small bushing (lower)

• 1 Bigger bushing (upper)

• 1 Bushing ring washer (upper)

• 1 Instruction note

One truck already consists of 11 (!) single parts and some of the parts have to be placed the right way up to make sure the trucks functions correctly. Two trucks double up to 22 (!) single parts. Luckily the trucks are pre assembled. We recommend NOT to take the trucks apart if not needed. It is sufficient to mount the wheels, set the steerance, secure the nuts and mount the trucks to the deck with the included 8 special screws. The 22 Truck parts + 8 screws + the Blackriver tool + key chain for the tool + sticker totals more than 30 (!) parts for each pack of trucks. One can sense all these small parts for such a small thing might indicate the trucks are not just a simple toy.

DECK ASSEMBLY

At best the trucks should be mounted to the deck directly when taken out of the package. Most decks/boards are still handmade and in most cases the holes in the boards are drilled by hand. This causes deck holes to be slightly crooked sometimes. When already having mounted 3 screws the fourth screw might need a lot of force to get mounted as well. If the last screw needs to much force the screw could damage the baseplate. With cheap baseplates it might not be fatal but it should be avoided when riding the BRR trucks. So when in doubt waive the last screw. When in doubt we advise to be content with only 3 screws instead of damaging the baseplate. Trucks are save even with only 3 screws. Fortunately this is an exceptional case.

WHEEL ASSEMBLY

With the Trucks assembled to the deck the next step is to mount the wheels. Simply loosen one of the nuts on the axle pin, place one bearing wheel on the pin and start mounting the nut a little. Do not tighten the nut to much. Wait until you have placed the second wheel on the other side on the axle pin securing it with the second nut. Remember the trucks have a passing axle pin so when over tightening the nuts you will cause the pin to be pulled out to far on one side not leaving enough of the pin on the other side to mount the second wheel and nut. Correctly mounted the passing pin sits centered in the hangar no matter how loose the pin was sitting before. It is NOT a defect when the passing pin is slidable! It was an intended feature of the first edition truck.

With the BRR Trucks 2.0 the passing pin is locked much tighter to prevent people to perform risky tuning moves. If you in spite of that over tighten a nut causing the pin to slide you can simply untighten the nut and pushing the pin back carefully. Do not use violence. When mounting the nuts the passing pin might turn around. In that case hold the pin on the other side by using a second tool or a small pliers.

HOW DO I PLACE THE PASSING PIN THE RIGHT WAY AROUND?

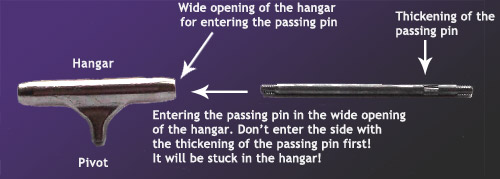

In case you took apart your truck make sure not to use to much force when reassembling the trucks. To much force might cause parts to bend, getting stuck or break. For normal use please do not take apart the trucks! The following picture however shows how to place the passing pin the right way round. Place the hangar on the table in front of you like shown in the picture. Make sure the pivot points toward you. The hangar has a tight and a wider opening. The wide opening points to your right. This is the end to enter the passing pin. The passing pin has a thickening at one end. The passing pin has to be entered with the other side first. Believe us, this is how your truck looks inside, you do not have to look yourself! The passing pin for the BRR Trucks 2.0 is sitting much tighter and is not intended being able to be taken out of the hanger!!

THE STEERANCE

The next step is to find out how you like your steerance. Try a few tricks adjusting the steerance by using the Blackriver tool. Tighten or loosen your kingpin nuts. It is a matter of taste how loose you like your bushings. Nevertheless we discourage you from over tightening the nuts. Rock hard steerance increases the pressure on the kingpin and bushings.

THE BUSHINGS

The bushings are made from a special material. Similar to skateboard bushings the material used here adapts to the riders individual preferences. In case you took apart the trucks it is important to make sure to place the bushings correctly whe reassembling the parts: The proper sequence is the baseplate with kingpin first, followed by the small bushing with the peak pointing down, the hangar next, the bigger bushing pointing up, a washer and nut. When mixing up the bushings the angles between hangar, pivot and kingpin is no longer correct. This will cause to much pressure on the pivot cup and kingpin and wear out the bushings crooked. A punctual overload like this can cause breakage of the kingpin.

NUT GUARD

In skateboarding the nuts for the axle and kingpin are big enough to feature a small plastic ring preventing the nuts from twisting off by themselves. The tiny nuts used for fingerboarding did not have these plastic rings because in most cases the nuts were to small for such a feature. Fingerboarders use nut guard“ (available from different brands) to make sure the nuts keep on place. It is similar to superglue with the important difference that the nuts still can be dismounted when using the right nut guard. Do not use the strongest nut guards.

Experienced fingerboarders use nut guard after they have assembled all parts. When using regular superglue it might be impossible to adjust the nuts causing the kingpins or axle pins to break when trying to turn the nuts. To prevent ruining your bearings, we advise you to place a drop of nut guard on a piece of paper . Take a needle or toothpick, dip it in the nut guard and use it to seal the mounted nuts. This way you can dose the nut guard. The BRR Trucks 2.0 however feature special and innovative locking nuts just like we know it from skateboards. These locking nuts make fluid nut guard no longer needed!

SLIDING BEARINGS

The BRR trucks are constructed to prevent the hangar from grinding out the back of the wheels. The new trucks spare the wheels averting unnecessary friction. The wheels are now using the bearings as intended.

The hangar is more narrow towards the end pieces to make the trucks only touch the bearings not the wheels. Depending on the brand, the edition and individual case it can vary how tight the the bearings are sitting inside the wheels. Too much pressure can cause the bearings to slide. On a case-by-case-basis the wheels will move onto the hangar getting stuck. Most wheel brands are ready with the next generation wheels where the bearings won´t slide. Flatface and Substance were the first hitting the streets with the next generation wheels. Winkler Wheels will be ready with special wheels soon. In most cases the old type of wheels will however function as well. Some might need a little tuning. Double bearing systems do also prevent the bearings from sliding. New wheel-types out or coming soon will fit these cleverly thought out trucks perfectly offering you a smoother ride, less friction and more durability.

DO ALL WHEEL BRANDS AND WHEEL ADDITIONS FIT THE TRUCKS?

In Skateboarding the different brands use the same size wheels and bearings while in fingerboarding a lot of different wheel systems and sizes can be found. A truck made to fit all wheel- and bearing types is possible, but it would need a slim and long axle pin making most bearing wheels sitting slackly on the trucks and the pins pointing out to far making scratches on tables and ramps when landing primo.

Working together with Winkler Wheels the year-long experience and quality products convinced us to chose the bearings and wheel dimensions used in Winkler Wheels products as a master. Nevertheless this does not mean no other brands do fit the trucks. Amazingly many different brands do fit the trucks and as stated before most brands have or will produce the new generation wheels with an improved bearing system. We can´t guarantee all wheels and bearings in the world will fit since in fingerboarding there is no production norm. When using wheels with the old bearing systems there are a few options if the bearings should start sliding.

Fingerboarders are clever and innovative. Some people carefully glue the bearings into the wheels (superglue, with a toothpick), others use washers and some loosen their wheel just a little bit giving the wheel more space to compensate pressure. All these options require dexterity and we recommend using wheels of the next generation. More tricks and tips can be found on ffi “fbweekly“ and other user-based web pages for fingerboarding.

REPAIR PARTS

To make the trucks last longer we have made special repair sets so you can exchange worn out parts instead of buying new trucks all the time. Different first aid sets are available.

WARRANTY

In-proper use can damage the trucks. The warranty spanned production faults not Inproper use, excessive force and/or ordinary wear out! in-proper use and production faults can clearly be distinguished when inspecting the single parts. Proper use however will make you have a lot of fun with the trucks. The wheels do not sit slacky, the bushings and the pivot-system provide you with a never before seen board control and with a little individual fine tuning these trucks become your trucks and offer fingerboarding at the highest level.

BLADE FINGERBOARD PARK VANCOUVER @ CALSTREETS