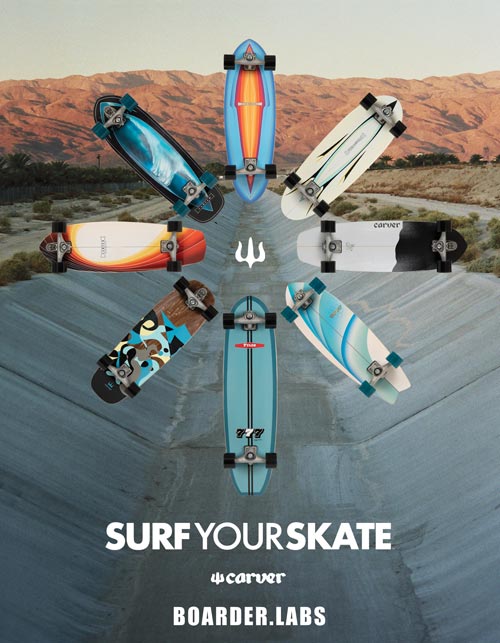

CARVER COMPLETES | CARVER TRUCKS | CARVER WHEELS | CARVER DECKS | CARVER PARTS

History of Carver Skateboards

It became clear that at the very least, the front truck would have to turn more than the back one in order to approach the turn dynamic of a Thruster surfboard.

Using angled risers and different combinations trucks and bushings, they returned to the hills to test their ideas. But just adding a little more turn to the front was only part of the equation. There needed to be some lateral sway, sort of like dragging the nose sideways while still in full contact with the pavement.

In order to achieve this, there needed to be some kind of flexible arm that allowed for this lateral movement, and after numerous sketches, they welded up the first Carver prototype truck in the derelict garage behind Neil’s house.

It was all just pure fun, “We just wanted a street surfer to ride, so we had to make one. Had there been anything available we would have gladly bought it and spent our time riding the hills instead,” Greg reminisced.But while many companies promised a surf-like skate experience, it was all just marketing and board graphics on the same trucks everyone had been riding since the ’70s.

After the welds cooled on the first prototype, they assembled their sway arm truck onto a board using thrust bearings for smooth rotation. But even on a moderate incline it was nearly impossible to ride.

When making a turn, the board banked in the wrong direction. It turned out that they had reversed the angle of the bearings, but in spite of the awkward handling, there was a hint of the movement they wanted. Back at the drawing board, they welded up a new truck with the correct angle for the thrust bearings, and returned to the hill. Now they felt the snap they had been looking for. All that month they went back to that little hill and skated those driveway banks like they were waist-high peelers. Many sessions ended prematurely, though, when one of them either bent a part, broke a weld, or something rattled loose. Even so, they wore down many sets of wheels testing those early trucks.

As they progressed and moved on to steeper inclines, they soon came up against the limitations of their prototypes. For one, the arm needed some kind of sprung resistance that brought it back to center, so Greg tied a bungee cord to the end of his truck and anchored it to the underside of the deck. It looked pretty bad, but it was a temporary solution that gave them more time on the hills. And while the angled pivoting arm now correctly tilted the deck into the turn, it did so at a fixed rate. So another improvement they needed was to vary the rail angle for more fluidity. Basically, it needed a second independent axis of movement.

The surfing feel of this new truck had been demonstrated over many sessions, but it still needed a lot of work to develop it into something beyond a handmade prototype. And with other surfers and skaters around Venice asking for these new ‘carving trucks’, the guys decided to produce a cast version so more of them could be made. Around then Neil was working with another friend, Eyreick, who was running the family aluminum foundry. His late grandfather, who built the business, had cast trucks for several local skateboard companies around Los Angeles since the early ’70s. Having also grown up in the old OC skating his neighborhood, Eyreick was as stoked on the idea of the new truck as they were, so together they decided to form a company to produce it. They called it Carver.

But there was still a lot of engineering to be done before the truck was ready for production. Taking time off from work, Neil began drawing the changes they needed. After months of drawing, he went into the shop and welded up the first truck that had a double-pivot universal joint. It incorporated everything he and Greg had learned from their months of testing, and packed it into a fairly compact mechanism.

“The afternoon I tested that prototype stands out as the first time I really felt that this could be something more than an experiment my buddy and I made. I didn’t even take it to a hill, but just circled around an inclined driveway a few doors down from my shop, but that was all it took.

I carved down the smooth cement, bottom turned and effortlessly pumped back up. After fighting with all those tricky early models, this one just disappeared under my feet. The double-axis mechanism allowed the board to turn at a variable rail angle, making it feel like I was riding on water. I stayed out on that driveway all night drawing figure eights all over that bank.”

While the carve was truly

While the carve was truly

magic, the compact spring idea didn’t quite work out, so they ended up strapping another bungee to the bottom of the board. Everyone that saw that prototype, and the one Greg rode, too, just shook their heads condescendingly. “I have to admit, I was embarrassed to show it around,” Neil said, “but the bungee worked well enough to get us back out on the hills testing the fine points of the geometry. It didn’t feel like some precarious prototype anymore. We were wearing down wheels to their cores every week, taking on the steepest hills we could find.” Months were spent researching all kinds of spring systems in search of something that could fit into the cramped little space under the arm and still hold up to the heavy-duty requirements of skating. Plus it needed it to be adjustable for different rider weights and preferences. It also had to increase in resistance towards the extremities, so it could act as a progressive stop. And if that wasn’t enough, it had to smoothly swing past a non-indexing centering bias, as most centering spring systems, like a swinging door spring, have an indexed ‘click’ at the center point. It turned out that what they needed didn’t exist yet.

magic, the compact spring idea didn’t quite work out, so they ended up strapping another bungee to the bottom of the board. Everyone that saw that prototype, and the one Greg rode, too, just shook their heads condescendingly. “I have to admit, I was embarrassed to show it around,” Neil said, “but the bungee worked well enough to get us back out on the hills testing the fine points of the geometry. It didn’t feel like some precarious prototype anymore. We were wearing down wheels to their cores every week, taking on the steepest hills we could find.” Months were spent researching all kinds of spring systems in search of something that could fit into the cramped little space under the arm and still hold up to the heavy-duty requirements of skating. Plus it needed it to be adjustable for different rider weights and preferences. It also had to increase in resistance towards the extremities, so it could act as a progressive stop. And if that wasn’t enough, it had to smoothly swing past a non-indexing centering bias, as most centering spring systems, like a swinging door spring, have an indexed ‘click’ at the center point. It turned out that what they needed didn’t exist yet.

Weeks turned into months as Neil tried to incorporate all of the disparate design demands into something that was simple, sturdy and easily made. After hundreds of drawings and many dozens of prototypes, and near the end of his strained credibility, he finally cracked the solution. “I felt confident with the design. Greg and I could finally go out for a skate and not bring a bag of tools with us anymore.” The process was taking much longer than anyone had anticipated, but with many solid solutions and so much already invested, they let the process dictate the pace, accepting no compromises.

So that next year was all about the design of the cast parts, how they could be best made and assembled, while being lightweight and strong. Compared to the uncertainty of designing the spring system, this part of the process was really fun. Translating the welded prototypes into masters for casting while knowing everything worked perfectly let the focus remain on making each part beautiful. Once a set of drawings factoring assembly clearances and casting draft angles was complete, sculpting the final masters began. These are the original parts, made around 3% larger than the produced parts in order to account for the amount molten aluminum shrinks as it cools. Masters are typically made from whatever works, in this case a combination of polystyrene plastic, wood and Bondo. And now that the design was complete they began the lengthy and expensive process of securing a patent for their innovative design.

Once the tooling and jigs were ready, they began making the new Carver trucks in small batches of several hundred and getting them into the hands of surfers and skaters. The feedback was great. Laird Hamilton got a hold of a board and immediately connected with the way it surfed. It was his perfect surf trainer to stay in shape for riding the giants of Peahi. An innovator himself, from tow-in technology to his revolutionary Foil Board, he recognized this breakthrough in skating and saw how it dovetailed with his own cutting edge pursuits. Since then Carver has proudly offered numerous Laird signature models, and continues to work with this legendary waterman to develop his quiver of land-surfing boards.

Japanese pro surfer-turned-distributor Aki Takahama also really felt the deep relationship to surfing he got when riding Carver, so he took some of the boards to Japan to see if anyone there would feel the same way. No one expected the intense response from the local shredders. Renowned Japanese pro-surfer Mineto Ushikoshi joined the Carver team, helping to design his own line of decks and graphics in conjunction with his U4 signature brand, and adding his technical surfing approach to the development of the Japanese Surfskate style. Orders came in faster than Carver could make them, and they got a crash course in supply and demand. It didn’t take them long to kick it into high gear, though, and soon thousands of boards were journeying across the sea. As the scene there grew, great riders emerged, and they developed their own distinctive style of surfskating.

Beyond the C7

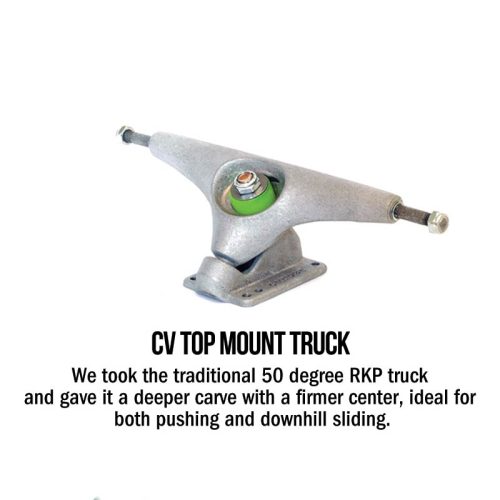

With this performance boost for the front truck, the back truck was feeling a little sluggish. So they took this ordinary workhorse, dubbed the C2, and put it through the same research and design process applied to the C7.

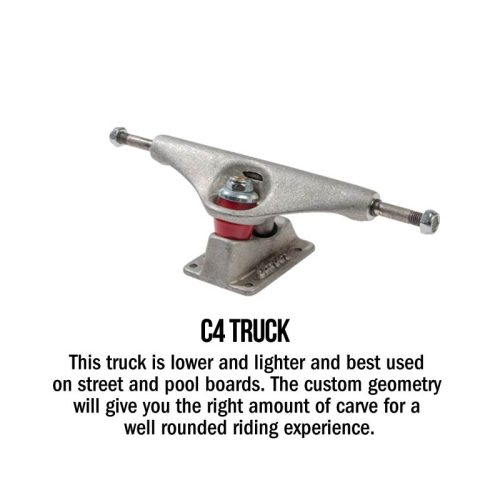

Among the improvements, they engineered it to turn a little tighter, and snap back to center positively. They also made a lower version, the C4, for street skating, with a reinforced slider plate and extra material on the hanger for longer grind wear. With the fundamentals now complete, there was a little time to just skate and surf and think.

Carver had created a fluid and reliable set of street surfing trucks, but there were other areas of the longboard market that needed to be addressed.

While there were plenty of riders who demanded the precision of the C7, there were others who just wanted a regular truck that gave them a surfier feel.

Basically, the same two castings, bushings and pivot pin, but reconfigured into a new geometry that loosened up the nose of the board and performed like a cross between the C7 and a standard truck.

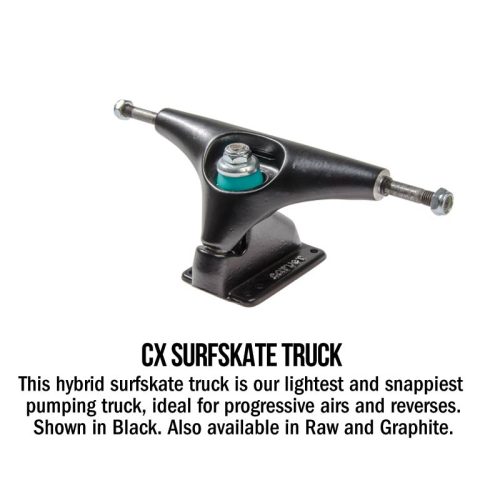

“I started calling it the CX, because it was a mystery to me, and instead of giving it a model number, I just wrote ‘X’,” said Neil about this new truck. He worked on in it spurts, trading between helping to build the Carver brand and diving into research and development.

After almost five years of making prototypes that didn’t work, it seemed as though it might be a futile pursuit.

Around this time, a large distributor approached Carver interested in taking their boards to the mainstream national market, and asked if they had a simpler model of carving truck. It was the perfect situation for the CX, so they took the latest prototype to the meeting, pitched them on the idea and they loved it. Only it didn’t work yet. All of a sudden the future growth of the business hung on solving that mystery. “I went through the previous years of research, skating the old prototypes in search of that feeling. I made graphs of the various elements of truck geometry and set about systematically charting the effects of various subtle changes on turning performance. For a few months, it was all about understanding what each angle and proportion felt like underfoot. For each new prototype I only changed one thing at a time so its’ effect could be isolated and measured,” Neil explained. With an understanding of these effects, he combined the elements he knew would produce the specific performance he wanted. To the casual observer, all the prototypes of that period look the same. Indeed, some of the changes were only a few degrees of kingpin angle, for example, but the effect on performance was dramatic. Comparing the first of that series with the last, the difference seems minute, but one carves and pumps, and the others just turn. In the end, that distributor ripped them off, nearly bankrupting the small company, but still it felt like they had come out ahead. They now had another important part of the line, the new CX.

Still Pushing Limits, Ten Years Later

Meanwhile, Greg had been pursuing the design of a skate tool that was as functional and well designed as the other products in the line. It was nice to be able to adjust the ride on the fly with a compact pocket tool, and all the available tools were either too big or poorly made. By now Carver had firmly established a protocol for product development; keep making prototypes until everything works perfectly, and only then move on to production. The consequence of this philosophy is that it takes an almost unreasonable amount of time to finish something. Few companies can afford such a protracted research and development program, but Carver wasn’t interested in just putting out another product. They were designing these things for themselves, and they needed to be completely satisfied with them. The formula is simple: more work you put into the initial design, the better it will work when you use it. Two years later they rolled out the Carver Pipewrench, a compact stainless steel skate wrench with a magnetic Allen catch that performs every adjustment a skater could need. With so much effort put into product design on the one hand, and manufacturing processes on the other, early marketing remained mostly word of mouth. Which was not so bad.

“We witnessed countless companies rush into the marketplace with hastily thought out products and big ad campaigns and then simply disappear the following year. We decided to build a long term, grassroots base and service it the best we could, and let our growth occur organically.” Eyreick observed.

It’s been ten years since that flat summer, and Carver is more solid now than ever. They’ve got the manufacturing down, the product line has grown with a full range of completes, apparel and accessories, and there’s a solid base of distribution that is expanding nicely. And as skating evolves to include the many styles re-emerging on the scene, Carver continues to develop new equipment for the all-around skater, helping to drive progression forward and supply the components for the complete quiver.

“I see people on our boards all the time now, and I love seeing how each skater brings their own unique mark to the style,” Neil said.

One thing, though, seems to stand out. Whoever is riding, they’re not just skating the street, they’re surfing the urban wave.

CARVER COMPLETES | CARVER TRUCKS | CARVER WHEELS | CARVER DECKS | CARVER PARTS